When I worked in Queensland, I asked my boss what is the best sewing machine ever made? His immediate reply was Bernina 830 Record. Fast forward a year or two and I've moved back to Melbourne. I'm friends with a sewing machine mechanic (Gordon Carr) who has worked as such since a young man in 1960. I asked him the same question and his immediate answer was also Bernina 830 Record. Both of them considered longevity, repairability and reliability.

|

| An 830 record in understated magnificence |

As a person who also sews, I can add ease of use. These machines are the central bobbin (CB) type which can handle the widest variety of different thread and fabric. There have been, and still are, thousands of CB machines on the market, but these are different. How can they be better than the others?

1. They're quiet. The manufacturing tolerances are very tight. Unlike other CB mechanisms, these machines don't rattle. The bobbin, bobbin case and shuttle all fit in perfectly and everything works with no problems.

2. They're reliable. The 830 was the result of evolution of Bernina records, starting with the 530 in the mid 1950s, continued through the 730 (from 1963 to 1971), then the 830. My ex boss had all sorts of machines as trade-ins, but would only sell on the 830s because he didn't want to fix a second hand machine under warranty and he had 100% confidence that he would never see any of the 830s again.

3. They all have a knee lift. Previous record models either don't have a knee lever at all or it was for operating the motor. That said, there were some from about 1969 on that had both a foot controller and knee lift, like the 830.

4. They have an easy five step buttonhole mechanism. The 530 and 730 had a buttonhole mechanism but it wasn't as easy to use as the 830s simple numbered dial.

5. Very sturdy. In March 2022, a lady came into the shop in Queensland with her 830 (that I happened to have sold her two months earlier). It was in her basement when the floods happened and was submerged in mud and water for three days! Gareth looked at the mess inside the case and to my surprise he said "yes that shouldn't be a problem". Afterwards I questioned his confidence, so he said that I could work on it. A bit over two hours later the machine was like new again! I doubt that another CB machine would have even survived such a trial, but for the Bernina it wasn't a problem.

You will find a lot said about these on the Internet. They keep their prices very well. I sold one in Melbourne for almost $1,000 in 2023, when other machines were hard to sell. You can buy a brand new Janome MyExcel for $599 but people will still spend much more on a 50 year old machine. The buyers aren't rich idiots.

Common problems and solutions

Pattern gear broken

|

| The nylon pattern gear |

Problem: The 830s pattern gear is nylon on a steel shaft. Over decades, the nylon shrinks and the gear cracks. The symptoms of this start with a slightly tight spot in the pattern cycle. When the crack widens, the needle starts swinging at the wrong spot, breaking needles.

Solution: Fit an aftermarket gear. You can buy them from various places, but I would advise avoiding random ebay shops. Get one locally and it's more likely to work. Some of the cheaper ones are either 3D printed (these do not last) or the tolerances aren't good enough (they're either too tight or too sloppy). These are the Rolls Royce of sewing machines, so don't use cheap parts. If you really want to DIY, the service manual is available as a download on both the vintage Bernina Facebook group and the groups.io Bernina BTS group.

Capacitor explodes

Problem: There is a capacitor pack connected to the motor. Capacitors don't last forever, and when they fail, they usually explode. The explosion is accompanied by the release of smoke.

|

| Capacitor pack is here |

Solution: Remove the motor and the inside cover, and you will see it as above. You can usually tell when a Bernina capacitor pack is starting to fail. They swell then crack. The crack gets bigger, then the action starts. Occasionally the capacitor will fail without any signs, but this is very rare. If your capacitor has just exploded, you can remove it in the very short term if you need to finish a job, but it should be replaced. The proper way to replace a failed capacitor is to buy a like for like one from Theodor Bastberget in Norway. If you don't want to spend that much, or wait until it arrives from Norway, you can just make one for the motor only from a 0.1uF X2 polypropylene capacitor from your local electronics store. You can cut two of the legs from the failed capacitor for the connectors and use shrink insulation. This is what I do. If you don't have a capacitor between the motor wires, there will not only be interference (which affects digital signals too), but the motor brushes will wear down much more quickly, and will deposit a mess of grey carbon on the motor's armature.

Can't access the patterns

Problem: Either can't move the selector to get a pattern or it's stiff and the patterns don't work.

Solution: Open the top cover and you will see this mechanism at the end of the selector lever. The two pronged part that moves is clogged with stuff that needs to be removed. Brush it with methylated spirits, move it then brush the part you just moved. Once it's clean you will be able to easily move it between the two extremes and it won't stay between them. At this time, a drop of oil or two where it moves will ensure that it keeps working.

|

| Stitch type selector |

Belt slipping

Problem: The belt slips

|

| Loosen the Allen screw |

Solution: You need a 4mm Allen key. Loosen the screw, tighten the belt and then the screw. Just be aware that the rule is to make the belt as loose as possible without it slipping.

Vertical gear

|

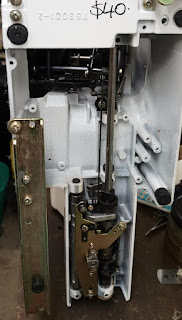

| The vertical gear is hard to access |

Problem: The vertical gear is broken As it says in the caption, these are hard to access. Thankfully this problem is relatively rare. I've only seen a couple of broken ones.

Solution: Same as with the pattern gear, get a quality part for DIY or get a sewing machine mechanic to do it. This is a lot more difficult than the pattern gear. Neal Iund made an excellent video on doing this for the 730, but the 830 instructions are the same, as are the gears themselves. I think that there are some that are different but these only apply to 730s.

Top cover won't open

Problem: You have to apply a lot of force to open the top cover, and once open it's floppy.

Solution: There is a small sliding part under pressure from a spring that moves when you lift and close the cover. The problem is that over time stuff accumulates and glues it to one spot and it won't go back. When you force it, it goes back and stays there, resulting in the floppy cover.

|

| The top cover's catch |

You can get this back to normal by brushing with methylated spirits and applying some pressure. It is much easier as usual if you heat it a little first, which softens the goo. Push it back, brush with metho and forward again. Repeat until it's very free. In my experience it doesn't take much effort or time. There's another one of these keeping the needlebar cover closed.

These machines are always worth fixing. For an old machine they command a large price for very good reason. Test one out and you will want it. Good machines will make you actually want to sew.